Description

TEST PROCEDURE

ASTM require a minimum length to diameter ratio of 2

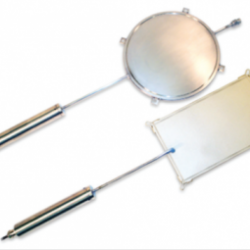

The ends of the rock specimen must be ground flat and parallel to 0.025 mm to 0.012 mm, depending on the diameter of the sample. The cylindrical rock sample is inserted into the Hoek cell within the confining membrane. The two spherical seats are positioned so that the rock core lies centrally in the triaxial loading frame press or chamber. The spherical platen will self centralise and confine the sample evenly through the loading process.

To hold the rock core in place one must apply a small confining pressure, the cell with its spherical seats is placed in a loading frame and a small axial load is also applied to keep everything in position. To determine Poisson’s ratio, a series of two orthogonal strain gauges are embedded in the membrane. Up to 6 sets of double orthogonal gauges are embedded for ample redundancy to determine poissons ratio. The strain gauges are read during the test via a hand held portable reader or datalogger. Third party devices that read RS232 serial output can be used to read the gauges through the ESS digitiser. The triaxial test may then be run after adjustment of the confining pressure to the required value.

Optional – The pressurisation system comprises of a hand pump, pressure gauge and high pressure hose with quick connect fitting. The pressure gauge is supplied with a calibration chart. When ordered together, the Hoek and pressurisation system are supplied in a rugged, reusable transport case. The Hoek cell is generally manufactured and supplied to operate with a core of particular diameter. The design is such that three basic units can be easily adapted to accommodate core diameters within the most commonly required ranges.

CORE DIAMETERS

Unit 1 110-150mm diameter (0-30 MPa) 50kg

Unit 2 70-110mm diameter (0-40 MPa) 40kg

Unit 3 40-70mm diameter (0-40 MPa) 30kg

CORE LENGTHS – Minimum 200mm

CELL TYPE – Hoek

PRESSURISATION SYSTEM – Enerpac hand pump with gauge and 1.5m hose

BOX/TRAVEL CASE DIMENSIONS – 86 x 43 x 40cm

FITTINGS – ¼” BSP

MEMBRANES WITH EMBEDDED STRAIN GAUGES

6 x two orthogonal 120ohm Strain gauges

12 Channel digitiser with serial RS 232 output

Breakout box power supply

APPLICATIONS

- Hoek Cells are designed for Testing Triaxial strengths of Rock or Concrete samples up to a Pressure of 40MPa. These are designed to accept samples of EX, AX, AQ, BX, BQ, NQ, HQ, HQ3, PQ, PQ3 and so on. Tests carried out on a series of samples under different confining pressures allow the user to determine:

- • Strength & Elastic properties

- • Shear strength at different confining pressures

- • Angle of Shearing Resistance & Cohesion

- • Modulus of Elasticity & Poisson’s Ratio